To read the data back, there are several options. We have already had great success in using lasers to read data from optical discs, albeit slowly. But anything that can hold small features etched into glass can work imaginatively.

Keeping the above considerations in mind, everything was fine at the theoretical level for Project Silica. The big question is how to put these together into a functional system. Microsoft decided that, to be cautious, it would answer that question twice.

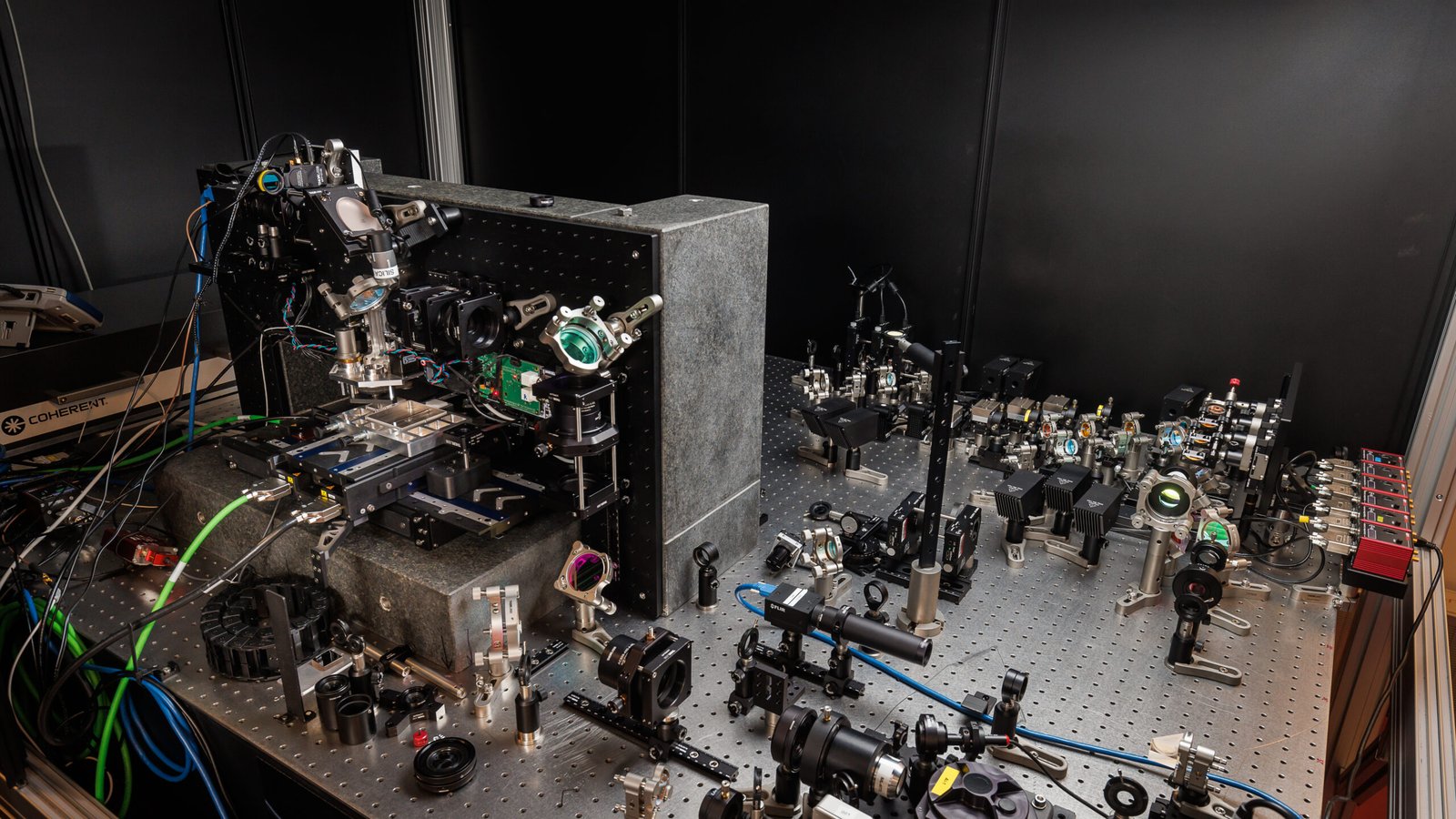

a real world system

The difference between these two answers depends on how an individual unit of data (called a voxel) is written onto the glass. One type of resonance they tried was based on double refraction, where the refraction of photons depends on their polarization. Using polarized laser light it is possible to etch tones in glass to create birefringence, producing features smaller than the diffraction limit. In practice, this involved using a laser pulse to create an oval-shaped void, followed by a second, polarized pulse to induce birefringence. Vowel identification is based on the orientation of the oval; Since we can resolve multiple orientations, it is possible to save more than one bit in each voxel.

Alternative approaches involve changing the magnitude of refractive effects by varying the amount of energy in the laser pulse. Then, it is possible to recognize more than two states in these voxels, allowing multiple data bits to be stored in each voxel.

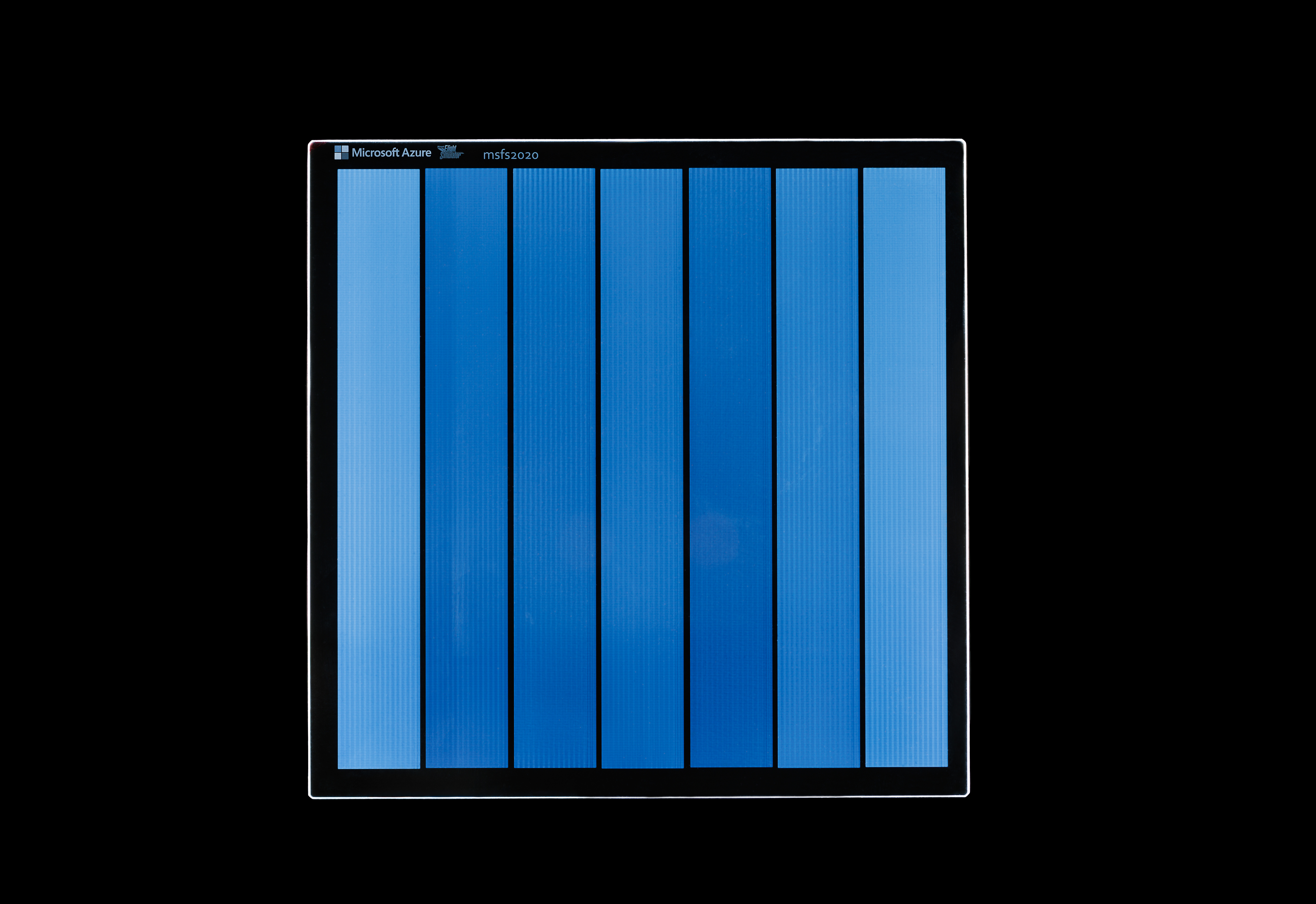

map data from Microsoft Flight Simulator Etched onto silica storage medium.

Credit: Microsoft Research

map data from Microsoft Flight Simulator Etched onto silica storage medium.

Credit: Microsoft Research

Reading these in silica involves using a microscope that can capture differences in refractive index. (For microscopy buffs, this is a way of saying “they used phase contrast microscopy.”) Microscopy limits how many layers of voxels can be placed in a single piece of glass. During etching, the layers were separated by a sufficient distance so that only one layer at a time was in the plane of focus of the microscope. The etching process also involves marking symbols that allow the automated microscope system to position the lens over specific points on the glass. From there, the system slowly changes its focal plane, moving through the stack and capturing images that include different layers of voxels.

<a href