Full-color, clear, vivid images have become essential in all visual applications, while energy conservation and carbon reduction are now global trends. Through a series of image tests, we will examine in depth the characteristics of Spectra 6 and CHLCD e-paper technologies, helping readers understand their strengths and weaknesses and choose the most suitable color e-paper for their applications.

How does Spectra 6 work?

The Spectra 6 features E Ink’s ACEP (Advanced Color ePaper) technology, which consists of microcups filled with four ink particles: red, blue, yellow and white. By applying different voltages, these ink particles can be moved to produce six standard colors: black, white, red, yellow, blue, green.

The Spectra 6 has micro cups of red, blue, yellow and white inks.

When electronic paper displays need to present colors beyond the specified six colors, an exact mixture of these six colors is required to simulate the same colors when viewed from a distance.

Cholesteric liquid crystal (ChLCD) e-paper has three layers of display that reflect red, green and blue colors respectively. The electric field alters the rotation of the liquid crystal which is bifurcated between two states:

- The liquid crystal particles in the planar state are lined up evenly to reflect specific wavelengths of light, creating unique colors.

- The focal conical stage aligns the liquid crystal particles in such a way that light can pass through them and the colors below are displayed.

Changing CHLCD particles on different layers to completely reflect light (white), partially reflect (gray), or no reflection (black).

By independently adjusting the position of the three RGB liquid crystal layers, ChLCD can perfectly reproduce more than 16 million colors, creating a richer color image than LCD.

difference in color palettes

Using this wider color palette as an example, the Spectra 6 displays high saturation in yellow but shows gaps in green tones with poor magenta and cyan. In contrast, ChLCD offers a much broader color display across all colors.

Left) Original image, Middle) Spectra 6 lacking cyan, magenta and green, Right) ChLCD with the full range of colors.

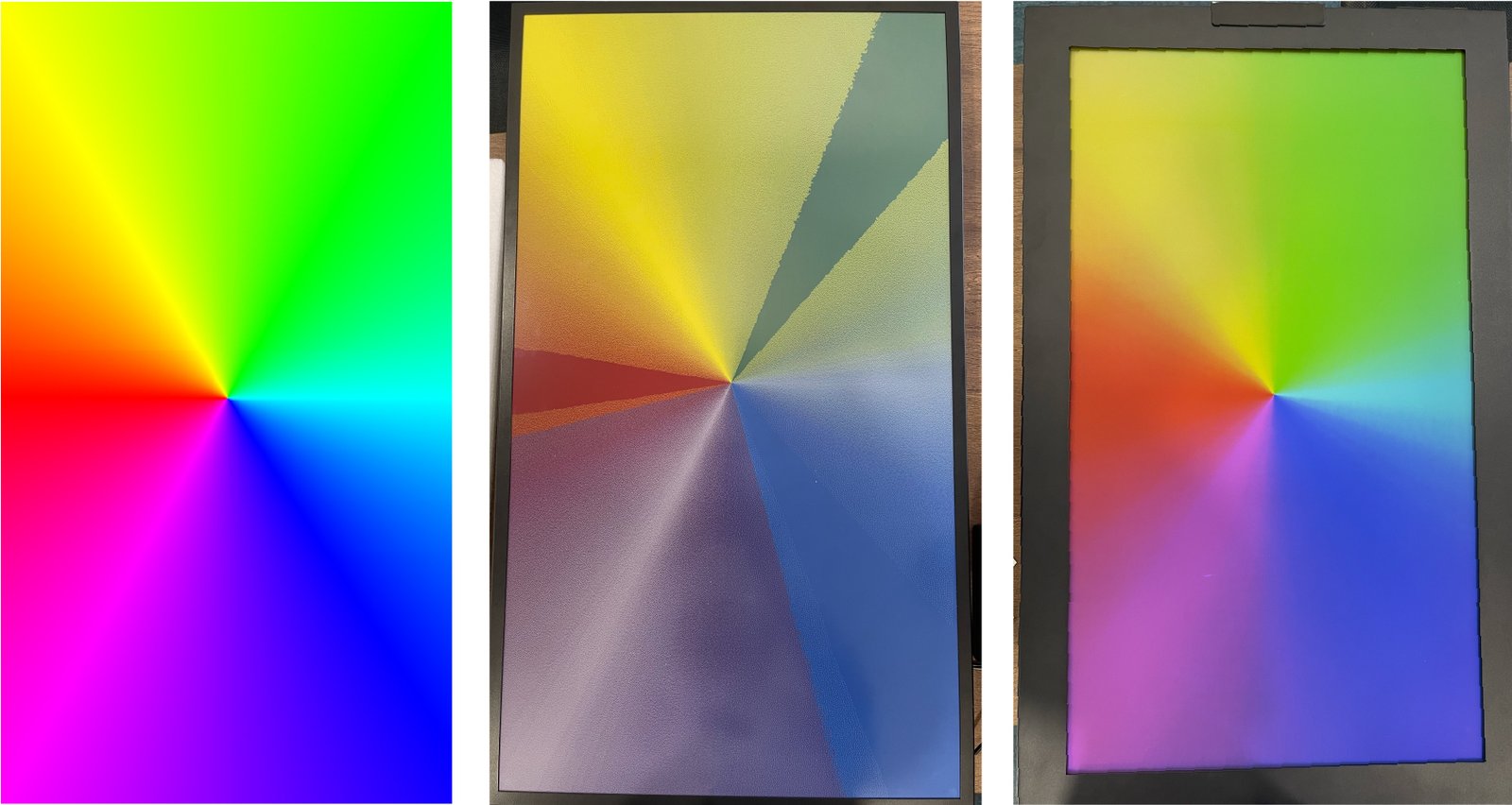

difference in gradient

A gradient image clearly shows the performance of different color e-paper technologies in the full-color gamut. In the case of Spectra 6, cyan appears as light blue, and magenta as purple. ChLCD, on the other hand, provides more accurate color representation with proper gradients in each color band.

Left) Original image, Middle) Spectra 6 displays cyan as light blue and magenta as purple, Right) ChLCD displays more accurate gradient display.

human figure

Human portraits and faces are common in advertising billboards, so precise image quality, smooth transitions between highlights and shadows and realistic skin tone reproduction are essential for accurate representation. In human images, Spectra 6 shows clear edges around the shadow, making the person look as if they are wearing a mask. While ChLCD provides a smoother shadow transition with better skin texture, eyebrows and more defined hair strands.

Left) Original image, Middle) Spectra 6 shows a sharp edge around the shadow on the face with grainy texture on the skin, Right) ChLCD renders fine detail in skin texture and hair.

food images

Color, aroma, and flavor are the core purposes of delicious food, and when the physical experience is not accessible, the importance of color becomes even more apparent.

Taking Spectra 6 as an example, the saturation and brightness of dragon fruit skin is significantly reduced. In contrast, CHLCD displays a more vibrant color for the skin of dragon fruit and a clearer, cleaner appearance for the flesh of kiwi.

Left) Original image, Middle) As seen in Spectra 6, the saturation and brightness of the dragon fruits are significantly reduced, Right) ChLCD displays more vibrant colors for the dragon fruits.

fashion advertising

In billboard applications, the wider color gamut better meets customer expectations. Taking a lipstick advertisement as an example, Spectra 6 shows a significant difference in the color representation of lipstick and lips compared to the original image, while the ChLCD’s display in magenta is close to the original.

Left) Original image, Middle) Spectra 6 shows brown lips and lipstick instead of pink, Right) ChLCD is very close to the original.

Overall, from the above comparisons, we can see that ChLCD offers better details, higher saturation and brightness. Its color rendition is close to the original image, which better meets market demands.

Outdoor Full-Color E-Paper Application

Outdoor displays have to withstand harsh conditions such as extreme temperatures, humidity and direct sunlight. To ensure that traditional displays operate reliably in all weather conditions, wide-temperature liquid crystals are essential.

Since ChLCD is based on liquid crystal technology, it can withstand external temperature variations. It is the only color e-paper in the market with an operating temperature of -20°C to 70°C. Even in direct sunlight, ChLCD can maintain vivid colors and is not affected by extreme heat or cold.

When paired with an IP56 or higher, UV-resistant casing, IRIS Optronics’ ChLCD e-paper can withstand wind, rain, and other outdoor elements. Whether it’s a freezing ski resort, a hot and humid beach, or a sunny golf course, cholesteric liquid crystal displays can deliver vibrant colors.

Speed difference between Spectra 6 and ChLCD

Besides color performance, another key metric for color e-paper is refresh speed. The more colored ink microcapsules required to control the EPD, the more complex the control method will be and the longer the update time will be. The 6-color Spectra 6 screen below requires about 15 seconds to refresh an image.

A ChLCD e-paper can drive three layers of RGB liquid crystals at the same time, and it only takes 1-2 seconds to update a full-color image.

Large size e-paper display

Large-sized displays are the mainstream digital display technology. Whether for business use or home entertainment, the demand for screen size is increasing. At the same time, ChLCD, which uses traditional LCD manufacturing processes, not only continues the stability and maturity of liquid crystal display technology but also effectively controls production costs. This makes ChLCD highly promising in achieving high-performance, cost-effective large-size displays. As technology advances, achieving screens in the 100-inch range is no longer an unattainable dream, but a near future.

If you want to know more about colored e-paper applications, please contact us.