America has a tungsten problem

America will need a lot of tungsten in the future. Where will it come from?

about tungsten

Tungsten is a metal with a unique combination of properties. It melts at a higher temperature than any other metal. It is very hard, extremely dense and largely inert. Unlike other refractory metals, tungsten conducts electricity and heat quite well.

Major applications of tungsten include:

- cutting and drilling tools. tungsten carbideIts extreme hardness and high heat tolerance make it a great material for drill bits; If you’re boring into the earth for oil and gas, you’re probably using tungsten carbide. This is now the primary application for tungsten; Estimates suggest that it accounts for about 60% of total consumption.

- munitions. Tungsten’s high density and chemical inertness make it useful in armor piercing rounds and some specialty explosives. It is an alternative to depleted uranium in many cases.

- semiconductor. Tungsten’s high melting point, inertness, substantial conductivity, and fluoride chemistry make it a useful metal for filling nanoscale connection gaps in semiconductors via chemical vapor deposition.

- photovoltaic cell. Traditionally, photovoltaic cell manufacturing (i.e., making solar panels) uses carbon steel wire to cut silicon wafers. Manufacturers are increasingly using tungsten wire instead, as it allows them to achieve much smaller wire diameters, which in turn reduces the amount of silicon wasted with a given cut.

Tungsten has an emerging application related to the future of energy: it is an essential input nuclear fusion reactor.

Tungsten is really good at resisting heat and corrosion from neutron bombardment. It is a leading candidate for radiation shielding in plasma-facing components and fusion reactors. ITER There are some good articles about why they use tungsten, including This one Regarding the extreme heat conditions that the parts need to endure.

Tungsten is a strange and mostly forgotten element. It does not attract as much attention as the rare earth metals. But it is really important for key industrial technologies!

demand for tungsten

Under steady state conditions, the United States needs to import about 10,000 tons of tungsten every year. And there may be US demand for tungsten going up. My hand-waving about threats estimates that the United States may need 15,000+ tons each year under somewhat moderate assumptions. If we allow ourselves to imagine fusion technology working, we can guess that the United States would have to find a way to match Chinese tungsten output.

Demand for tungsten: traditional applications

If we refer to the main applications of tungsten, we must understand that the demand is likely to increase. Let’s engage in a thought experiment with an extremely simple model:

- Assume that the amount of tungsten consumed in a given application varies proportionally with the overall size of the market. Why not? Looks ok.

- Specify some vague distributional assumptions for various applications that consume tungsten. Let’s say 60% of tungsten goes to cutting and drilling, 10% goes to munitions Semiconductors 5%1% for photovoltaic applicationsAnd then 24% for a bunch of other stuff. Let’s round Fusion to zero for now.

- Specify some vague high/low estimates for different applications. Let’s assume semiconductor and photovoltaic applications grow at a 15% compound annual growth rate (CAGR) and assume everything else grows slowly at a 5% CAGR.

We arrive at a bleak model estimate of tungsten demand almost doubling (+77%) over 10 years. Of course, all these statistics are inaccurate, but that doesn’t mean they aren’t useful.

The important conclusions we must draw here are all qualitative. Demand for tungsten in the United States is growing under relatively conservative assumptions.

| cutting and drilling | 5.0% | 60% | 63% | 66% | 69% | 73% | 77% | 80% | 84% | 89% | 93% | 98% |

| munitions | 5.0% | 10% | 11% | 11% | 12% | 12% | 13% | 13% | 14% | 15% | 16% | 16% |

| semiconductor | 15.0% | 5% | 6% | 7% | 8% | 9% | 10% | 12% | 13% | 15% | 18% | 20% |

| photovoltaic | 15.0% | 1% | 1% | 1% | 2% | 2% | 2% | 2% | 3% | 3% | 4% | 4% |

| Other | 5.0% | 24% | 25% | 26% | 28% | 29% | 31% | 32% | 34% | 35% | 37% | 39% |

| Total | 5.9% | 100% | 106% | 112% | 118% | 125% | 132% | 140% | 148% | 157% | 167% | 177% |

Tungsten Demand: What About Fusion?

I intentionally left out fusion above. What if this really happens? There Are There are a lot of talented people working hard to make Fusion possible. There’s ITER, as I mentioned earlier, but there’s also a bunch of commercial startups. It is not impossible that some of these organizations make real progress over the next decade.

Many people smarter than me have invested time and credibility in the promise of fusion on the horizon. For example, DeepMind partners with CFS, Microsoft agreed to buy electricity from Helion EnergyAnd Helical Fusion arranges power purchase agreement with a major Japanese supermarket. Even when you cut through the PR here, there’s undoubtedly a grain of genuine optimism.

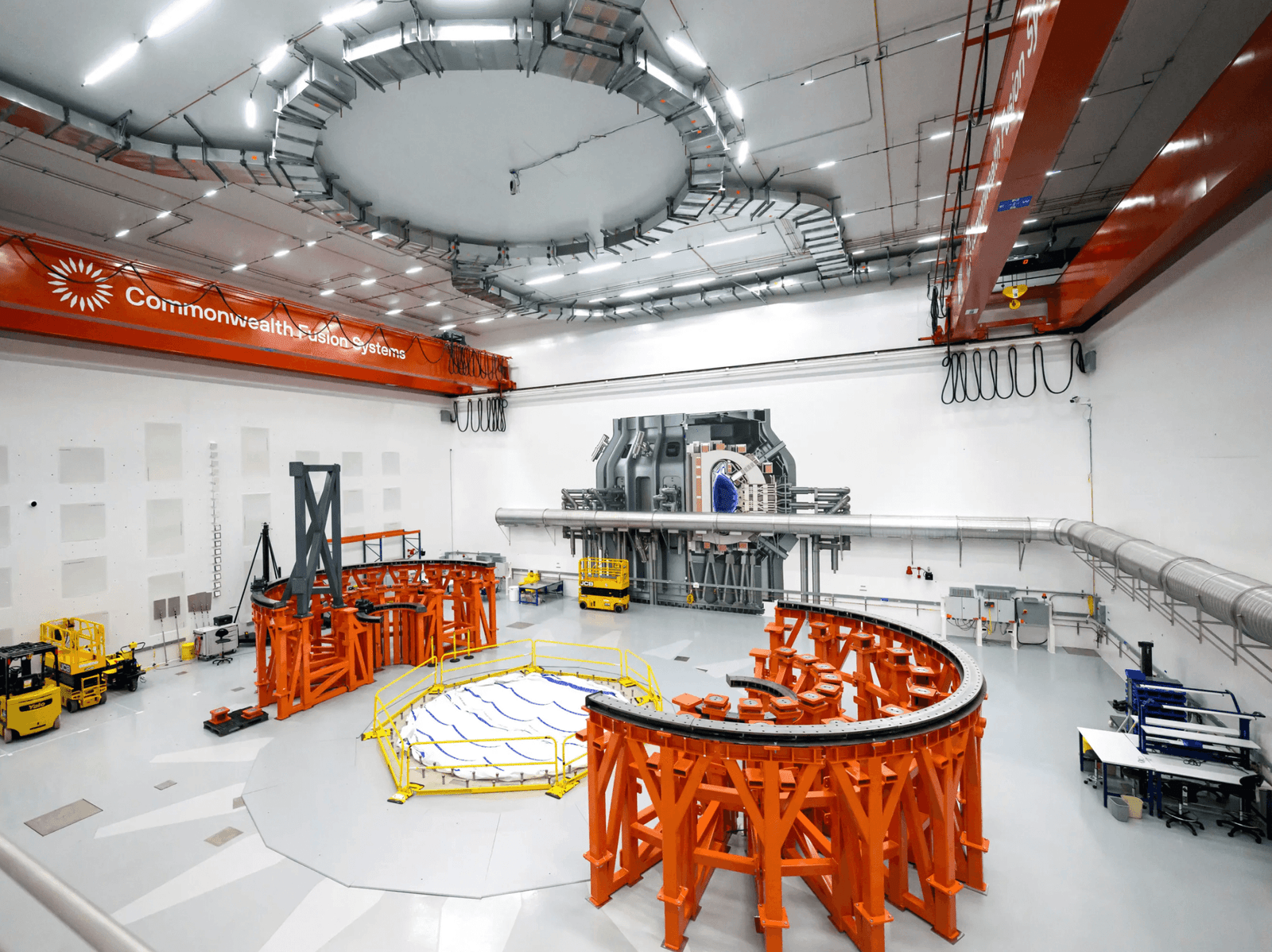

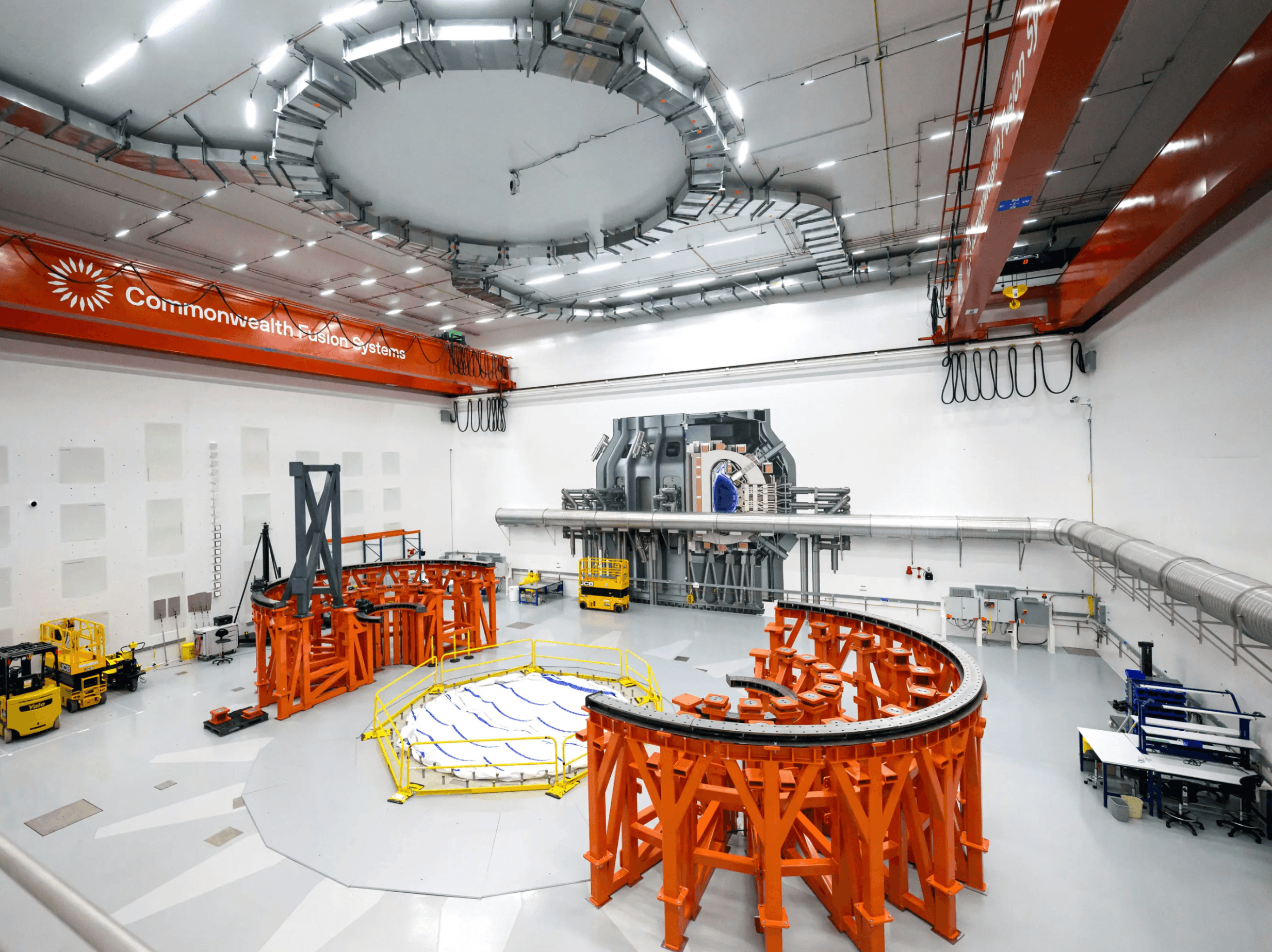

An image from the CFS’s Tokamak Hall

I can’t pretend to know what a fusion reactor’s appetite for tungsten would be. I really don’t know. I have little doubt that no one knows.

i got it a paper out there. The paper suggests that a fusion reactor could consume 5,000 to 30,000 tons of tungsten over a 40-year lifetime. Let’s say for simplicity the answer is 10,000 tonnes over 40 years. This amounts to 250 tonnes per reactor per year.

What is the appropriate number of reactors? Here again, I cannot pretend to know. I can only point hastily to the numbers fragmentation Reactors that we already have. We know that there are about 100 civilian fission reactors in the United States. And then the US Navy has another 100 or more nuclear reactorsMostly on submarines.

In the absence of any good reason to believe otherwise, one can imagine that the United States might demand 200 or so fusion reactors. This is again almost certainly an incorrect figure, but it is still useful for qualitative judgments.

if this is true Fusion could account for most of future US tungsten demand. 200 reactors at 250 tons of tungsten per year produce a total of 50,000 tons of tungsten per year.

If we combine this figure with our bleak baseline projection from earlier, we can envision tungsten demand in the United States reaching 60,000 to 70,000 tons per year.

tungsten supply

Tungsten is a major Chinese industry; Each year, China accounts for more than 80% of the world’s ~80,000 tonnes of production. The next largest producing countries in a given year are usually Vietnam, Russia, and North Korea – and none of them are really major producers.

The United States has not produced Any Tungsten since 2015.

Global tungsten production, by year

Figures in metric tons

Source: USGS Mineral Commodity Summary.

The United States has long been dependent on China for its tungsten supply. The United States has historically imported approximately 10,000 tons of tungsten each year. In that quantity, where else could tungsten come from? no other country produces About Sufficient!

Recent trade disputes have made US dependence on Chinese tungsten hard to ignore. In response to the tariffs, the Chinese government imposed strict export controls on minerals, including tungsten. To date, no American firms appear to have received a Chinese export license for tungsten. Control is functionally equivalent to restriction, even if no one wants to call it that.

US-China relations are somewhere in between competitive And adversarial. I will leave the characterization to the personal politics of the reader. In any case, US dependence on Chinese tungsten (among other minerals) compromises its strategic position. The United States currently has no alternative supply of tungsten.

US tungsten imports for consumption, by year

Figures in metric tons

Source: USGS Mineral Commodity Summary.

Supply cannot just appear. It takes many years and many millions of dollars for mines to reach full productivity. Mines need to raise lots of speculative capital, navigate a complex regulatory maze, recruit specialized labor, and finally… get a little lucky. Furthermore, the mining business tends to decline rapidly and then head into recession every few years. You can’t really count on sustainable availability of private capital.

The natural solution for US interests would be to encourage tungsten production elsewhere – whether domestically or abroad. There is simply a need for more non-Chinese tungsten.

it Is Going on, at least to some extent. US War Department has made some awards to American and Canadian firms that are developing tungsten mines. Trump administration steps forward A US-Kazakh tungsten deal At the end of last year.

But maybe this is not enough. We need to seriously consider the scale of the problem here. US demand for tungsten already exceeds non-Chinese supply by a large margin. We can see this in market prices, which have reached all-time highs in recent weeks. And the demand is probably increasing.

wrapping up

As things stand, the United States is facing a problem. The country does not have a secure, viable supply of tungsten for the future. The United States therefore puts its domestic semiconductor and munitions industries at risk in the medium term.

But an even bigger strategic challenge lies ahead in the next decade. Optimistic predictions about nuclear fusion may prove correct. We may have functional – it is not yet economical – commercial fusion in the 2030s. If this is true, demand for tungsten will rapidly outstrip supply. Prices will increase.

The obvious solution is to mine more tungsten. After all, it turns out that tungsten isn’t really that hard to find! It’s all over the United States. In fact, it is almost all over the world.

One wonders:

- Why does China produce more than 80% of the world’s tungsten?

- why has it happened Zero Domestic tungsten mining in the United States?

- What changes are needed for the comeback of domestic tungsten mining?

- What will it take to ensure tungsten supplies last through the next boom and bust mining investment cycles?

<a href