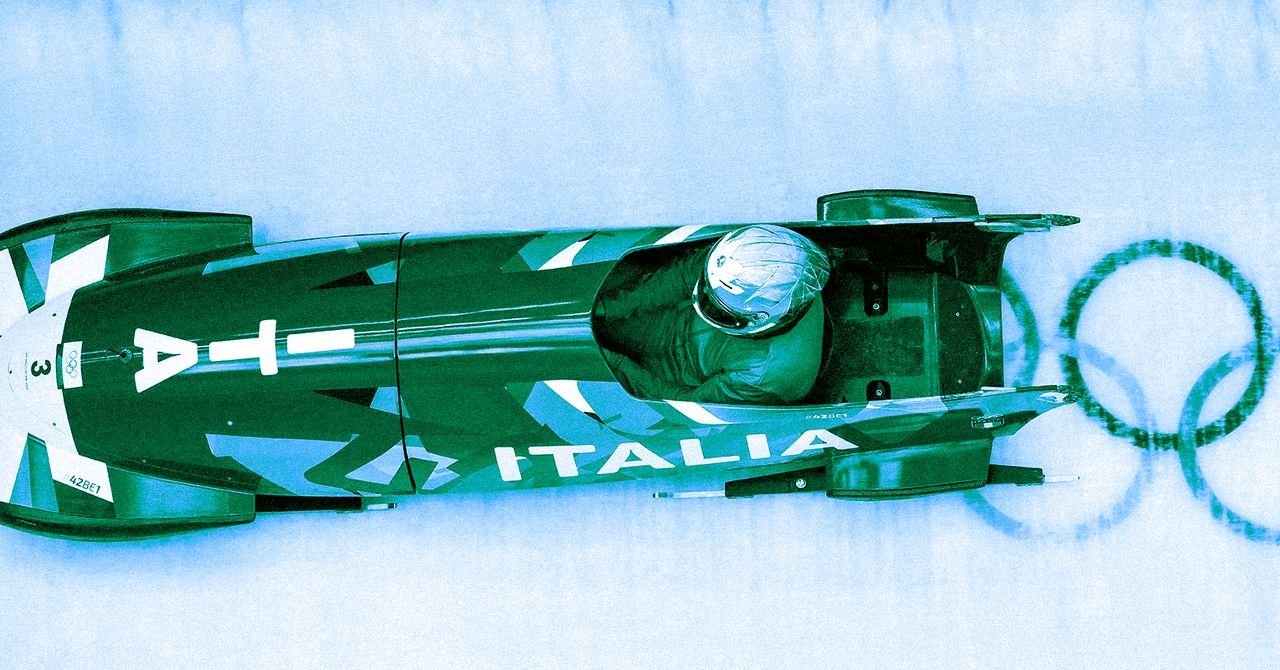

Men’s four-man bobsledding made its Olympic debut in Chamonix, France in 1924; Women’s two-person bobsledding did not enter the Games until 2002 in Salt Lake City. Women’s monoboob arrives in 2022. While early bobsleds were made of wood, the sport has been synonymous with steel for years, although in recent decades this has been replaced by carbon fiber, which offers greater lightness and strength.

Every new technological development in the sport has come amid constraints necessary to keep athletes safe, such as weight and sled size. A two-person bobsleigh can have a maximum length of 2.7 meters (about 8.9 ft) and a maximum weight of 390 kilograms (859.8 lb), including crew. A four-person bobsled cannot exceed 630 kilograms (1,388.9 lb) including bobbers, and cannot exceed 3.8 meters (12.47 ft) in length.

The weight limit was a necessary step to equalize racing conditions and curb the use of athletic specialists, who, although not bobsledders, had in the past proven decisive in the success of their teams through the pushing phase. This is far from coincidental, as this is one of the areas where technology has the greatest impact on bobsledding.

At the 2022 Beijing Olympic Games, Germany won 27 medals, 16 of which came from bobsledding, luge and skeleton. German athletes excel in bobsled because the sport has a long tradition in Germany, but also because the country has long focused on innovation in the sport. Automaker BMW, for example, is a strategic partner of the German federation that oversees bobsledding, luge and skeleton (Bob- und Schleitenverband für Deutschland) and is credited with introducing custom studded shoes, a key tool for bobsled performance.

The first 30 to 50 meters of an Olympic bobsled often prove decisive in the race, as this is the only time when athletes can push the sled to reach maximum acceleration. A few years ago, BMW realized that innovations in bobbers’ footwear could improve their performance during that critical time.

Taking into account each team member’s preferences, BMW created custom spike plates that can be integrated into any type of shoe. Using 3D printing, the company was able to customize the stiffness and shape of the studs for different shoes and needs. Working in this way allowed him to rapidly experiment and modify designs. To avoid excessive wear and tear, the spikes are given increased hardness through plasma nitriding, in which nitrogen is ionized in a high-temperature vacuum and diffused into the steel.

<a href